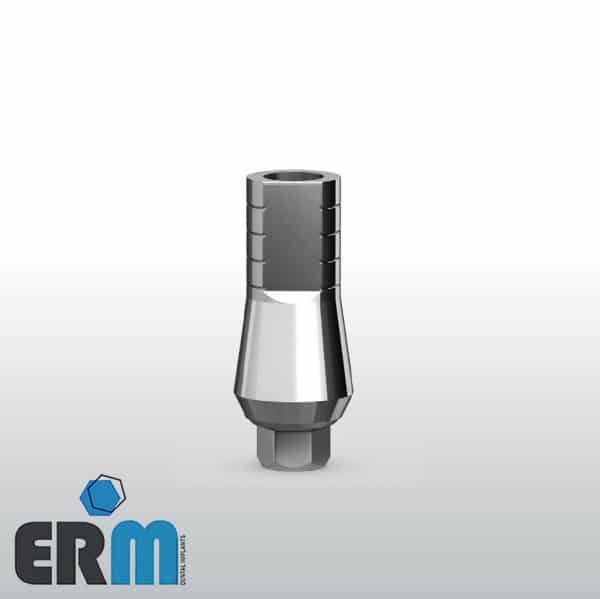

TITAN METAL SCREWS + STRAIGHT ABUTMENT

- Internal Hex System

- Hex Size 2.42 mm

- [SP] Standard Platform

- Same Prosthetic Platform For All Implants Diameters

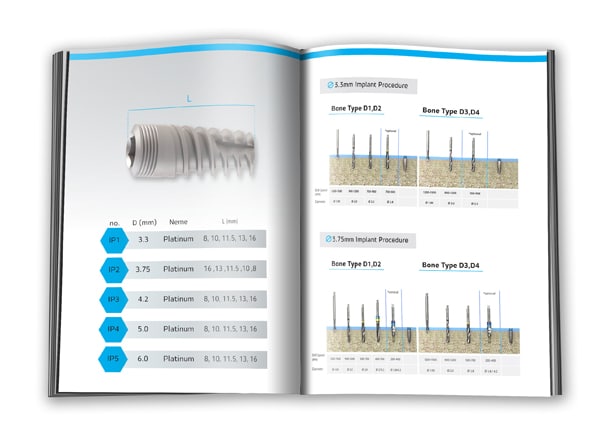

- Diameter’s size: ø 3.3 , ø 3.75 , ø 4.2 , ø 5.0 , ø 6.0 (mm)

- Length’s Size: 6 / 8 / 10 / 11.5 / 13 / 16 (mm)

- Package Includes: ERM Premium Ultra Pure Platinum implant + Straight Abutment with Fixation screw.

- Material: Titanium Ti-6AL-4V-ELI.

Our spiral implant is unique.

The product is based on traditional and proven design of tapered implant that’s threaded, balanced and has dynamic self-drilling capability.

Outstanding tapered implant’s symmetrical structure that contributes to balance efforts and equal distribution of possible loads during implantation and for the duration of use.

UNIQUE DESIGN FEATURES

- Tapered

- designed to allow for additional space for bone growth

- Two micro threads

- Platform switching

- Osteotome-like condensing body

- Pronounced tapered core

- Apical part with sharp deep threads

CLINICAL BENEFITS

- Optimal primary stability

- High bone preservation

- Increased early BIC

- High bone condensation

- High initial stability

- Self-drilling

Internal Hexagon Connection 2.42mm

These series of implants with internal hex connection are of very high precision, mechanical strength and guarantee long durability.

IMPLANT STRUCTURE

The implant is strongly built, has stable body with durable blades that collect at the comers, convene the soft bone and compresses it during implantation to ensure the uniform and high-quality platform for connecting the bone graft.

The implants are equipped with uniform connection platform that allows the use of identical parts of rehabilitation after transplantation.

ADVANCED UNIQUE APPROACH SURFACE TREATMENT

ERM Dental implants are treated with state of the art Advanced

Unique Approach surface treatment procedures.

This treatment includes sand-blasting, acid etching and extensive cleaning. This treatment creates macro, micro and nano surface structures, enlarging the Bone to Implant Contact (BIC), thus promoting osseointegration and early restoration.

Our company has adopted the method of surface treatment based on SLA technology using high quality materials to create Topography required on the one hand; and on the other hand has chosen principle, not to use chemicals and industrial pollutants.

The success and safety of dental implants is greatly dependents on the surface composition. Additionally The company decided to use citric acid, which naturally stabilizes and is a key component in the process of ERM’s extensive multi-stage cleaning removes undesired residues derived from manufacturing, yielding a contamination-free surface.

The use of acid ensures that the implant will be absorbed very well and will avoid rejection of implants resulting from From Absorption failure. This process is based on years of experience in clinicals Research’s and hundreds of thousands of implants manufactured and implanted around the world.